Conversion efficiency from 3.8% to 25.5%, perovskite only took 12 years. It took only about one and a half years for perovskite to overcome the world-class stability problem.

In 2009, when Japanese scientist Tsutomu Miyasaka first used perovskite solar cells to generate electricity, the photoelectric conversion efficiency was only 3.8%. At that time, the conversion efficiency of the crystalline silicon cell laboratory had reached about 18%. In just 12 years, the highest record of conversion efficiency in perovskite laboratories has reached 25.5%, which is close to the current most efficient hetero junction, TOP Con and other crystalline silicon technologies, which will be a few blocks away from other technical routes that are also thin-film batteries.

In the view of industry insiders, conversion efficiency is no longer a limiting factor in the application of perovskite batteries, and more critical is the stability of its industrialized products.

Stability overrides everything, and it is also the key to the success or failure of the industrialization of perovskite technology. Compared with crystalline silicon, the efficiency improvement rate of perovskite is quite eye-catching, but the physique is inherently weak.

As we all know, different from the attenuation mechanism of crystalline silicon modules, the structure of traditional perovskite light-absorbing materials is easily destroyed under long-term light and heating conditions, resulting in rapid degradation of battery performance and weaker natural physique, so stability has also become a perovskite technology research and development .And the world-class problems that need to be solved urgently in the mass production process.

For stability testing and certification of perovskite products, two factors need to be considered: standards and testing agencies. Since perovskite battery technology has only begun small-scale mass production in recent years, perovskite batteries and modules have not been considered in the photovoltaic cell standard. At present, the certification of perovskite products can only temporarily refer to the certification standards of crystalline silicon components, which also means that the certification results obtained by this standard basically represent the current progress of industrialization of perovskite battery technology.

The certification tests for photovoltaic crystalline silicon modules in the International Electrotechnical Commission (IEC) 61215 standard are mainly divided into the following categories: Performance test, Chamber test, Electrical shock & Harzard tests), Machanical stress tests, Outdoor test. The IEC 61215 standard also includes individual and sequence tests to evaluate the long-term reliability of components outdoors.

According to reports, improving the intrinsic photothermal stability of the structure and composition of perovskite materials and encapsulating the battery are the main means to solve the problem of perovskite stability. Although there are many enterprises and academic institutions involved in the R&D and production of perovskite technology, most of the test results of academic institutions focusing on perovskite technology are single tests, which can launch perovskite components that meet mass production standards and pass stability certification, but very few.

"Stability overrides everything", who is leading?

In fact, according to "Global Photovoltaics", so far, only Sina Optoelectronics has publicly disclosed the stability report of its perovskite products through third-party tests, including aging tests and tightened tests, which are solving the problems of perovskite technology. A breakthrough has been made in terms of stability issues.

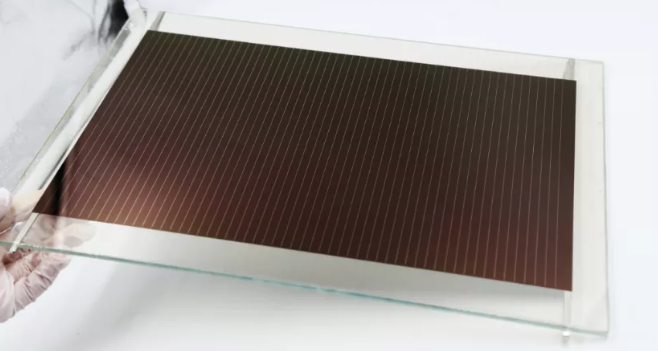

In 2019, Sina Optoelectronics' perovskite components passed the four environmental chamber aging tests in the IEC 61215:2016 standard, namely the cold and hot cycle test, the photo-aging test, the damp-heat aging test and the ultraviolet aging test. The test results show that the conversion efficiency of the components after aging are all equivalent to the initial value.

This is the world's first product certification of a perovskite component that meets the IEC 61215 standard, which means that the perovskite technology has officially stepped out of the laboratory and entered the market, starting a new journey.

In early 2021, the perovskite components of Sina passed the stricter test of the three environmental chamber aging tests in the IEC 61215:2016 standard by the third-party authoritative certification body German VDE and Thiel Labs, each with a 1000 h Photoaging test (under 1 standard solar irradiance, module aging temperature is 70oC), 3000 h damp heat aging test, 100kWh ultraviolet aging test, the conversion efficiency of the module after aging is equivalent to the initial value. This certification is also the world's first IEC 61215 standard perovskite component product certification.

In fact, the above-mentioned two certification results represent that the stability of the perovskite module of Sina Optoelectronics is basically equivalent to that of other commercialized technologies, and even far exceeds the previous stability expectations.

Technology leads innovation, perovskite standards need to be customized

However, some industry experts reminded that the certification of perovskite products temporarily refers to the IEC 61215:2016 certification standard for crystalline silicon photovoltaic modules. However, the light-absorbing materials and other functional materials of these two products are different, and the temperature coefficients are also different. Therefore, when formulating the test standards for perovskite products, it is necessary to highlight the stability of the weakest link in accordance with the battery performance characteristics and attenuation mechanism. Perovskite components are applied in real life.

"For example, the temperature coefficient of a perovskite module is different from that of a crystalline silicon module, and the required stabilization period and module pretreatment methods are different before testing; the thickness of the perovskite module is thin, and it can quickly reach a stable state under the sunlight simulated light source. It does not need to be pre-processed according to the crystalline silicon module test standards; in addition, due to the influence of the hysteresis effect, the positive and negative sweep performance of most perovskite modules are different, and the test method will also affect the conversion efficiency and module power when testing.

Perovskite modules represented by Sina Optoelectronics have repeatedly made breakthroughs in stability, but more field applications are still needed to test the degree of commercialization of perovskite photovoltaic technology. At present, MW-scale pilot lines have been launched one after another, and the research and development of perovskite tandem cells has gradually entered the right track. At the same time, in the arena of solar cells, a series of technical genres, efficiency records, testing and certification, etc. The controversy continues.

In any case, the type of technology that is expected by the industry to change the process of the photovoltaic industry-perovskite technology is shining brightly and fighting for the future!

View More(Total0)Comment Lists