Technical characteristics and installation requirements

of solar cell modules

Solar cell modules are made of high-efficiency monocrystalline solar cells/polycrystalline solar cells, low-iron ultra-white suede tempered glass, packaging materials (EVA, POE, etc.), functional backplanes, interconnect bars, bus bars, junction boxes and aluminum alloy frame composition. The service life can reach 15-25 years.

1. Basic requirements of solar cell modules

1. It can provide sufficient mechanical strength, so that the solar cell module can withstand the stress caused by shock and vibration during transportation, installation and use, and can withstand the click force of hail;

2. It has good sealing performance, which can prevent the corrosion of solar cells from wind, water and atmospheric conditions;

3. Has good electrical insulation properties;

4. Strong anti-ultraviolet ability;

5. The working voltage and output power are designed according to different requirements, and a variety of wiring methods can be provided to meet different voltage, current and power output requirements;

6. The efficiency loss caused by the combination of solar cells in series and parallel is small;

7. The connection of solar cells is reliable;

8. Long working life, requiring solar cell modules to be used for more than 20 years under natural conditions;

9. Under the conditions mentioned above, the packaging cost should be as low as possible.

2. Technical characteristics and installation requirements of solar cell modules

1. The solar cell array consists of one or more solar cell components. If there are more than one components, the current and voltage of the components should be basically the same to reduce the loss of series and parallel combination.

2. Determine the total power of the solar cell array according to the local solar radiation parameters and load characteristics; determine the number of series and parallel components of the solar cell array according to the voltage and current requirements of the designed system.

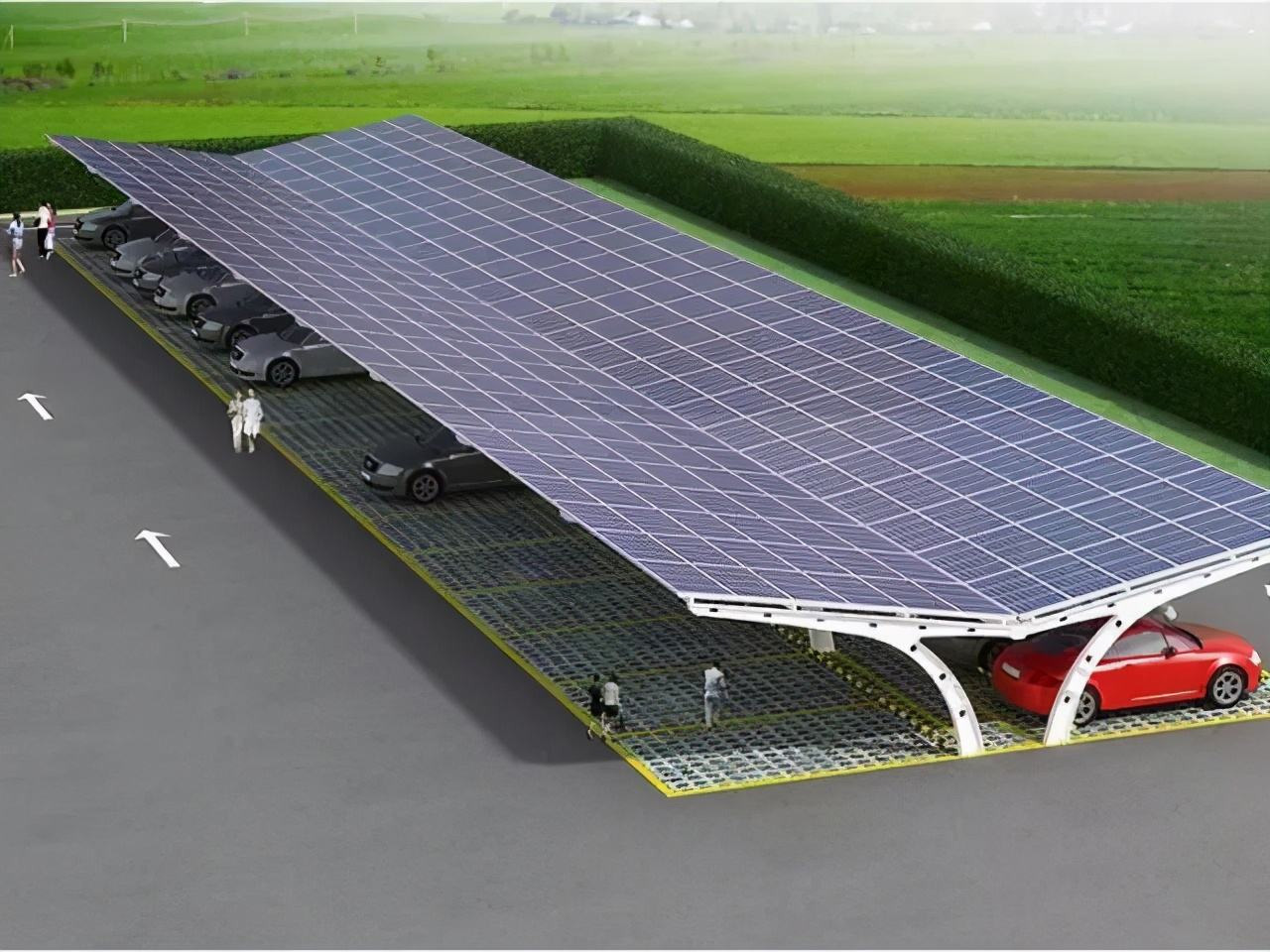

3. The solar cell square bracket is used to support the solar cell module. The structural design of the solar cell array should ensure that the connection between the module and the bracket is firm and reliable, and the solar cell module can be easily replaced. The solar cell array and support must be able to withstand winds of 120 km/h without being damaged.

4. The bracket can be adjustable in inclination, or installed at a fixed angle, so that the solar cell array can obtain the maximum power generation in the design month (that is, the month with the worst average daily radiation).

5. All the fasteners of the phalanx must have sufficient strength to reliably fix the solar cell module on the phalanx bracket. The solar cell phalanx can be installed on the roof, but the phalanx bracket must be connected with the main structure of the building, not on the roof material.

6. For ground-mounted solar cell arrays, the minimum distance between solar cell modules and the ground should be more than 0.3 m. The bottom of the column must be firmly attached to the foundation to be able to bear the weight of the solar cell array and to withstand the design wind speed.

7. For portable low-power power supplies, the solar panel should have a bracket to make it reliable.

View More(Total0)Comment Lists